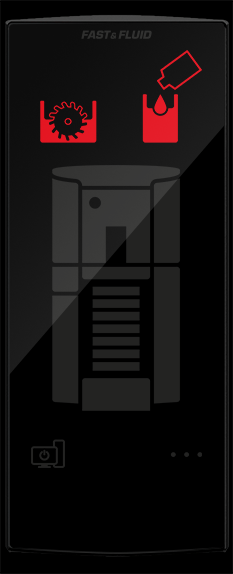

Optimize your operation with the

Harbil® ZeroPurge™ Piston Pump

- No purging

- High speed

- Easy serviceability

Benefits:

The ZeroPurge piston pumps eliminate the manual purging process and autonomously flush the dispense channels at night, leaving no room for idle colorant anywhere in the system. Zero colorant waste, minimal maintenance, and a dispenser that's always ready for action!

Speed is of the essence in your day-to-day operation, without losing any of the tinting accuracy. The Harbil ZeroPurge Piston Pumps offer an impressive flow rate that ranges from 0.5 to 2 l/min, depending on the pump size, and a minimum dispense of 0.05 ml.

The intelligent design makes serviceability more effortless and efficient than ever before. The heavy-duty materials combined with easy-to-reach parts used in all Harbil Next Gen dispensers means that replacing a seal is now literally done in less than a minute.

See it in action

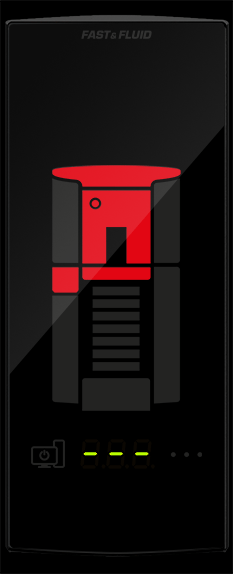

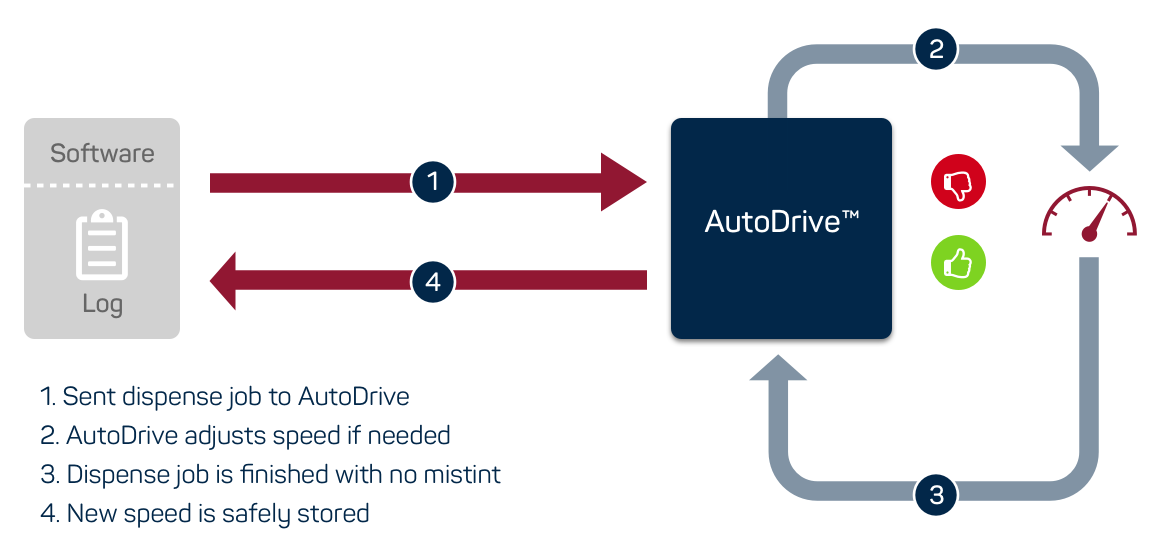

Ultimate reliability at high speed:

The AutoDrive™

- Ultimate reliability at high speed

- No more colorant-related mistints

- Efficient and accurate diagnostics

Benefits:

We understand that achieving precision results with complex colorants can be a challenge. In fact, overcoming these challenges is precisely what makes our Harbil dispensers so highly regarded. But besides reliability and low-maintenance, our customers also demand a quick dispense time with accurate results.

Always starting at the highest speed, the AutoDrive detects challenging colorants and, if needed, adjusts to the maximum possible dispense speed to finish the job. This happens so fast that the operator doesn't even notice. The result? An error-free, reliable dispense process in the shortest possible time!

The driver software is in constant contact with the AutoDrive and stores any possible changes securely on the Service Dashboard. This real-time information ensures your service technician always has access to efficient and accurate diagnostics.

How it works

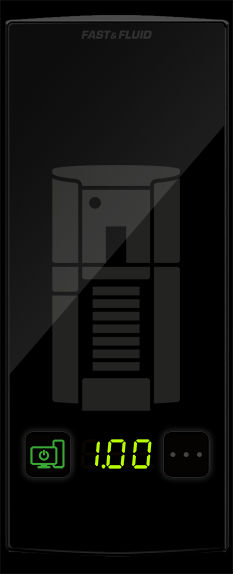

Manage your machine at

a glance: The Operator Display

A Service Dashboard that translates

data into relevant information

- Translate data into clear info

- From reactive to proactive

- Remotely accessible

Benefits:

Information is key in running an effective service organization, which is what the Service Dashboard on the Harbil Next Gen Series is all about. With one clear overview, you have insight into your dispenser, colorant and housekeeping status information.

Because all vital information is easily accessible - even remotely via a teamviewer connection - you can become more proactive in maintaining your dispenser.

Why change parts too soon? Or too late? The Service Dashboard tells you exactly when parts, e.g. the piston seals, need replacing based on their travel distance. This guarantees the lowest cost of ownership and minimizes downtime of your dispenser.